Enhance the Pre-Inspection Process

By: John Miller

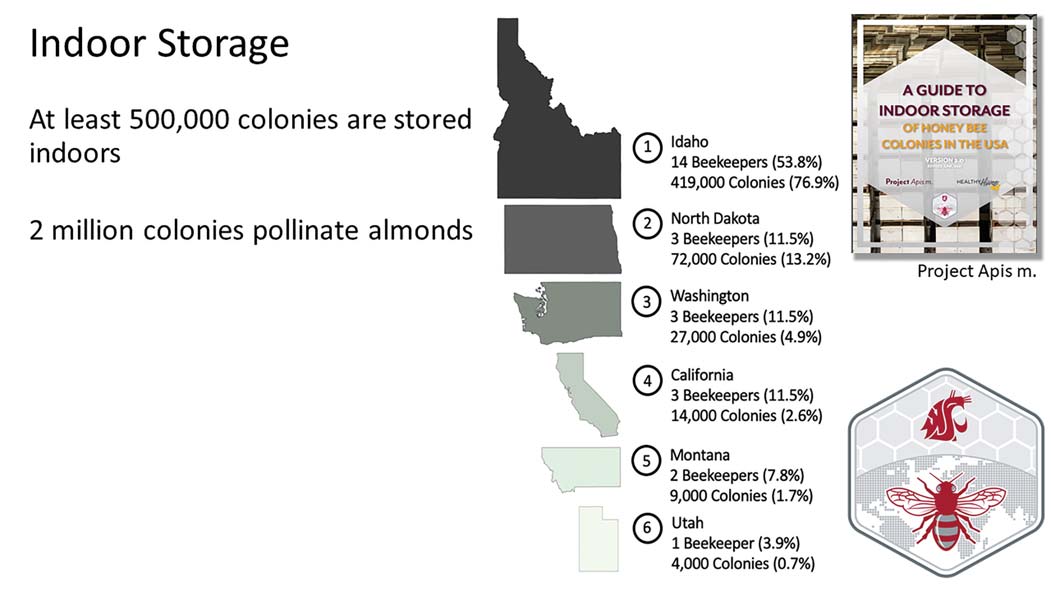

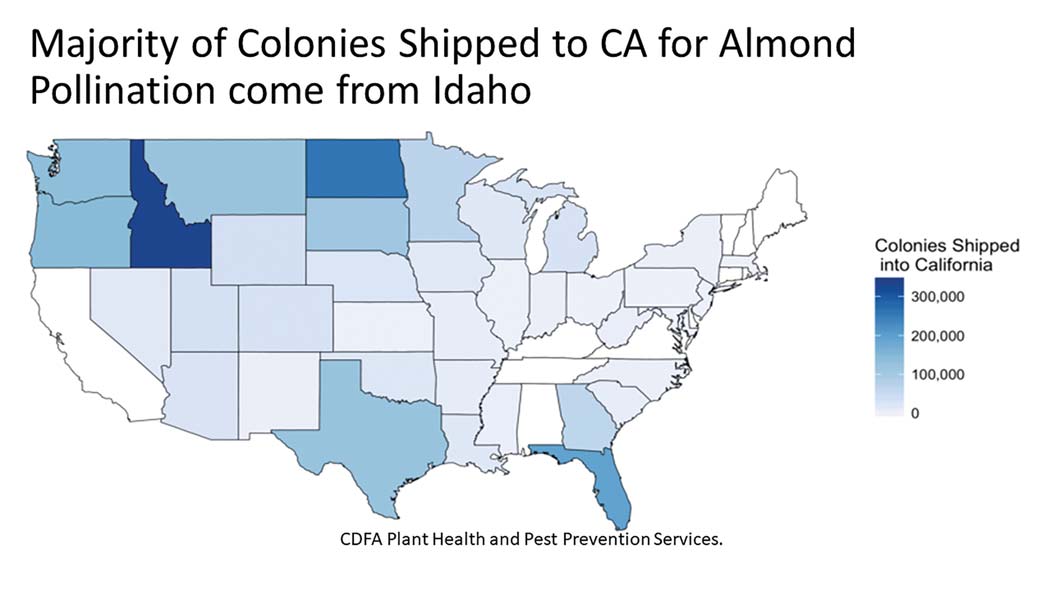

Indoor beehive storage buildings designed for beehives now house nearly a million beehives. Over 400,000 of those hives are stored in Idaho alone. A new building recently opened in Laurel, Montana. New buildings opened in Idaho and North Dakota in 2021.

87% of perhaps two million hives pass through Truckee California bug station annually. That is over 4,000 loads of bees going through one lane at one bug station, with two overwhelmed Pest Exclusion agents, ledgering every single load of bees.

In 2019, a pilot project to pre-inspect beehives in the originating state was introduced. The idea is to expedite passage through Truckee. The idea is to minimize the traveling publics exposure to loads of beehives stacked up, sometimes 12 trucks deep. The idea is to alleviate the two overwhelmed inspectors from donning hat, veil, and flashlight – lifting nets, peering into loads [sometimes well after dark or prior to dawn] attempting to detect fire ants, hive beetles and weeds and field debris. Both pre-inspected and uninspected loads wait their turn to present paper work, to be legered. The idea of pre-inspection is to address these bug station clusters when a swarm of bee hauling semis arrive…and swarms of semi’s bottleneck at Truckee.

This is especially important now; from January 10 to February 10 about 2,000 of those 4,000+ loads pass through the Bug Station. One unintended consequence of the current pre-inspection program is that drivers of these pre-inspected loads wait their turn with other loads of uninspected hives.

This wait-in-line bottleneck creates needless delays, a key goal of Almond Board of California, Blue Diamond Almond Growers Cooperative, the Apiary Inspectors of America, and the North Dakota Commissioner of Agriculture, and California Department of Food and Agriculture all collaborating to reach a Memorandum of Understanding on the Beehive Pre-Inspection Program. After North Dakota and California implemented the pre-inspection program, other states quickly recognized the opportunity.

How can this process be improved?

When a load dispatches from an indoor facility, a Bill of Lading accompanies the load. Attached to that document is a certificate of facility pre-inspection. After a building is inspected, and found free of ants, beetles, weeds, and cow patties, a certificate for the number of hives in the building is issued. Each time a load dispatches from the building, the number of hives on the semi is deducted from the eligible total. After all the loads are shipped, the permit totals are reconciled with the number of hives actually shipped, to ensure the shipper complies with the terms of the pre-inspection.

This part of the process works great.

Opportunity for improvement lies in how the information is shared.

Could the Bill of Lading with the attached identifying detail be scanned and sent to the Department of Pest Exclusion – or directly to a Bug Station email account dedicated to pre-inspected operations? The number of indoor wintering buildings is less than 50.

Before shipping pre-inspected hives commences, a folder for each indoor building operator could house all the relevant data for that operator – In Truckee – Readily Available. As each load ships, an email alerts Truckee. The tractor number, the trailer number, the number of hives, a phone number point of contact, the destination, as much data as the participant can provide would fit in one email attachment – or fit on an Excel spreadsheet attachment.

Simpler yet, a bright yellow placard in the windshield could visually signal to the Bug Station inspector that This Load Has Been Pre-Inspected. The placard could display the operator’s I.D. number so the inspector could visually match the load to the in-house spreadsheet.

Another possibility is to print QR codes [think of restaurant menu QR codes replacing those sketchy paper menus quickly passing into extinction] to match the number of pre-inspected loads. The shipper attaches a QR code to the Bill of Lading so the Bug Station Inspector scans the QR code – the information is captured, immediately – then reconciled with the shipper-authorized number of eligible, pre-inspected hives.

An important component of any pre-inspection program is compliance. For example – over 10,000 loads of certified weed-free hay pass through Truckee annually. If a load shows up in the dairy, say 300 miles down valley from Truckee – and is found to be infested with noxious weeds – a sanction occurs. If the load of hay is rejected – it can’t be set on fire on site – it gets rejected. The shipper of formerly certified weed free hay looses certification – and access to the biggest dairy hay market in America.

Indoor building operators adhere to a higher standard of inspection. Indoor wintering operators should enjoy the benefit of expedited passage; and conversely, if they game the system, loose access to the program.

The pre-inspection program grew out of a need to address a serious bottleneck in a specific place for a specific purpose. The stakeholders adopted a pilot program that worked, and now enjoys Memorandum of Understanding status between the agencies, the almond growers, the truckers, and inspectors.

Above are a few possible solutions to refine the process – and get those rigs rolling.